- Phone:+86 15218629499

- Phone: +86 15766990063

- E-mail: Yzprinting01@163.com

When it comes to packaging solutions, Plastic Pouch Packaging has gained significant popularity across various industries due to its versatility and efficiency. This innovative option not only enhances the shelf appeal of products but also provides exceptional durability and protection for a wide range of goods. Whether you are in the food, beverage, or consumer goods sector, selecting the right type of plastic pouch is crucial for ensuring product integrity and appealing to your target audience.

Choosing the appropriate Plastic Pouch Packaging involves careful consideration of various factors, including material types, sizes, closures, and sustainability options. Understanding these elements can greatly influence the effectiveness of your packaging strategy, ensuring that your products reach consumers in optimal condition while also aligning with their preferences for eco-friendly solutions. As the demand for custom packaging continues to rise, mastering the art of selecting plastic pouches is essential for maintaining competitiveness in the market.

In this article, we will explore ten essential tips that will guide you through the decision-making process, enabling you to make informed choices about Plastic Pouch Packaging. By focusing on crucial aspects of design, functionality, and sustainability, we aim to equip you with the knowledge needed to elevate your product offerings and satisfy customer needs effectively.

When selecting plastic pouch packaging, it’s crucial to understand the variety of options available to meet different product needs. Plastic pouches come in several types, including stand-up pouches, flat pouches, and vacuum-sealed pouches, each serving unique applications in various industries. According to a recent Smithers report, the global flexible packaging market (which includes plastic pouches) is expected to reach $300 billion by 2026, driven by the growing demand for convenience and sustainability.

Stand-up pouches, for instance, are popular for their stability and visual appeal on shelves, making them a preferred choice for snacks and beverages. Flat pouches, on the other hand, are typically used for smaller items or single-serving products, making them a cost-effective solution for food and non-food applications. Vacuum-sealed pouches are ideal for extending shelf life by removing air, which is particularly beneficial for perishable goods. According to an analysis by Market Research Future, the vacuum packaging segment is projected to grow due to consumers' increasing focus on food preservation and waste reduction.

Understanding these types allows businesses to make informed decisions about their packaging needs. Evaluating factors such as product compatibility, barrier properties, and consumer preferences will help in selecting the appropriate plastic pouch. In a market that values sustainability, options like biodegradable or recyclable pouches are also gaining traction, aligning with consumer trends towards environmentally friendly choices.

When selecting plastic pouch packaging, evaluating material durability and barrier properties is crucial to ensure product integrity and longevity. The choice of material should be driven by the specific needs of the product it will contain, as different materials offer varying levels of resistance to moisture, gases, and other external factors. For instance, high-density polyethylene (HDPE) offers good chemical resistance and can be a suitable choice for items that require moderate protection from environmental elements.

On the other hand, multi-layer films can provide enhanced barrier properties, making them ideal for packaging products sensitive to oxygen or humidity.

Additionally, it’s essential to consider how the packaging will be utilized throughout its lifecycle. Products that may undergo fluctuating temperatures or rough handling during transportation demand packaging that can withstand such stress without compromising its protective qualities. Evaluating the puncture resistance, tear strength, and overall robustness of the material can help ensure that the packaging remains intact from manufacturing to consumer use. By carefully assessing these factors, businesses can choose plastic pouch packaging that not only preserves the quality of their products but also enhances their overall market appeal.

When it comes to selecting the right plastic pouch packaging, determining the appropriate size and shape for your product is crucial. An ideal pouch not only protects the contents but also enhances the product's visibility on the shelf. Start by assessing the dimensions of your product. Consider its width, height, and depth to ensure the packaging provides a snug fit. A well-fitted pouch minimizes excess material, reduces shipping costs, and creates a more appealing presentation. Additionally, think about the overall aesthetic—while a sleek, modern design may attract consumers, a more robust shape might be necessary for fragile items.

Beyond dimensions, the shape of your pouch can significantly impact user experience and functionality. For example, stand-up pouches provide stability and visibility on retail shelves, while flat pouches are excellent for space-saving and convenience. If your product requires easy access, consider incorporating a resealable feature, ensuring customers can securely close the pouch after use. Tailoring the size and shape of your packaging to the specific needs of your product will enhance its usability and appeal, ultimately contributing to customer satisfaction and brand loyalty.

| Tip Number | Tip Description | Size Considerations | Shape Considerations |

|---|---|---|---|

| 1 | Consider Product Dimensions | Measure height, width, and depth accurately. | Choose a shape that accommodates product comfortably. |

| 2 | Account for Fill Weight | Ensure the pouch can hold the total weight of the product. | Consider a gusseted bottom for heavier products. |

| 3 | Identify Storage Constraints | Consider shelf space and storage capabilities. | Flat pouches are great for limited space. |

| 4 | Evaluate User Experience | Ensure easy opening and resealing options. | Stand-up pouches enhance usability for consumers. |

| 5 | Consider Packaging Design | Match size with design elements for visibility. | Unique shapes can attract buyer attention. |

| 6 | Assess Environmental Impact | Choose sizes to minimize waste. | Consider recyclable or biodegradable shapes. |

| 7 | Select Proper Material | Choose the correct thickness for size. | Consider materials that hold intended shape. |

| 8 | Evaluate Distribution Requirements | Ensure sizes fit within shipping logistics. | Select shapes that optimize shipping space. |

| 9 | Test with Prototype Packaging | Prototype size for final product fit. | Experiment with various shapes for effectiveness. |

| 10 | Gather Feedback from Customers | Use customer feedback on size and usability. | Adapt shapes based on consumer preferences. |

When choosing plastic pouch packaging, it's crucial to assess the environmental impact and sustainability of your options. Many traditional plastic materials contribute significantly to environmental pollution, taking hundreds of years to decompose. However, advancements in biodegradable and compostable materials offer more sustainable alternatives without compromising on functionality. Selecting packaging made from these innovative materials can significantly reduce your ecological footprint. Additionally, it is essential to consider the recyclability of the packaging. Pouches designed for easy recycling can promote a circular economy, allowing materials to be reused and reducing the demand for virgin resources.

Furthermore, understanding the life cycle of your packaging is key to making an informed choice. This assessment includes the extraction of raw materials, energy consumption during production, transportation emissions, and end-of-life treatment. By evaluating these factors, businesses can opt for solutions that minimize negative environmental impacts. Engaging with suppliers who prioritize sustainable practices and transparency can also enhance the overall sustainability of your packaging choices. Ultimately, mindful selection of plastic pouch packaging contributes not only to a healthier planet but also to a positive brand image that resonates with environmentally conscious consumers.

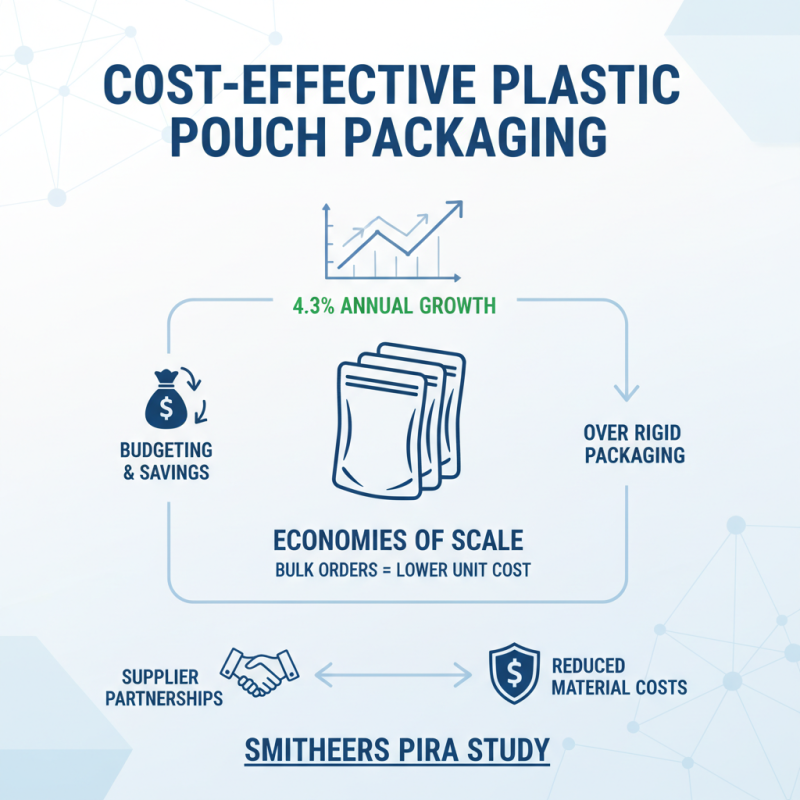

When selecting plastic pouch packaging, budgeting and cost considerations are paramount to ensure your investment aligns with your business goals. A recent study by Smithers Pira indicates that the flexible packaging market is projected to grow by 4.3% annually, driven largely by the cost-effective advantages it offers over rigid packaging options. Therefore, businesses focused on reducing packaging costs should consider the economies of scale that plastic pouches can provide, particularly when ordered in bulk. Additionally, with the right supplier partnerships, companies can benefit from lower material costs, which significantly impact the overall production budget.

In terms of material choices, it’s critical to analyze the cost implications of different types of plastics like PE, PET, or biodegradable alternatives. According to a report by MarketsandMarkets, the average cost of plastic resin has fluctuated, with increasing prices expected due to global supply chain disruptions. This makes it essential for businesses to evaluate long-term contracts or alternative materials that still maintain product integrity while minimizing expenses. By closely monitoring industry trends and understanding the lifecycle costs associated with different packaging options, companies can make informed decisions that will ultimately enhance profitability and sustainability.