- Phone:+86 15218629499

- Phone: +86 15766990063

- E-mail: Yzprinting01@163.com

In an increasingly competitive global market, the demand for high-quality PP bag packing solutions has surged, driven by the growing packaging industry, which is projected to reach a staggering $1 trillion by 2026 according to Smithers Pira. As businesses strive to enhance their operational efficiency while reducing environmental impact, selecting the right manufacturers of PP bag packing is crucial. A study by Mordor Intelligence estimates that the PP bag market alone will witness a compound annual growth rate (CAGR) of 4.8% from 2021 to 2026, highlighting its essential role in various sectors including food, agriculture, and industrial applications. This upward trend emphasizes the importance of partnering with top manufacturers who can deliver innovation and sustainability. In this blog, we will explore key factors to consider when choosing quality PP bag packing manufacturers to ensure your business remains at the forefront of packaging solutions.

As we look forward to 2025 and beyond, the market for polypropylene (PP) bag packing solutions is poised for significant growth, driven by evolving consumer preferences and increasing industry demand. The global food packaging market, valued at $500.27 billion in 2024, is anticipated to reach $533.22 billion in 2025, eventually surpassing $815.51 billion by 2032. With the rising consumption of ready-to-eat foods and e-commerce, the need for efficient and sustainable packaging, including PP bags, is paramount. This trend highlights the critical role of top manufacturers in providing innovative packing solutions that cater to diverse market needs.

To ensure that your business remains competitive in this dynamic landscape, consider the following tips: prioritize working with manufacturers who focus on sustainable materials and processes, as the eco-friendly trend is gaining traction among consumers. Additionally, invest in advanced packaging technologies that enhance shelf-life and reduce food waste, which is becoming increasingly vital in maintaining supply chain efficiencies. Finally, stay informed about industry trends by accessing comprehensive market reports that provide insights into growth patterns and emerging opportunities.

As the market continues to expand, especially in niches like anti-static packaging and tea packaging, leveraging data will be essential for making informed strategical decisions. For instance, the anti-static packaging market is projected to grow significantly, driven by sectors such as electronics and aerospace. This presents a unique opportunity for businesses that can adapt their packaging solutions to meet specialized needs while driving innovation in their offerings.

When selecting high-quality polypropylene (PP) bags, it is crucial to consider several key features that indicate durability and functionality. According to a report by MarketsandMarkets, the global PP bag market is projected to reach USD 11.67 billion by 2025, emphasizing the increasing demand for reliable packing solutions. One of the essential characteristics to look for is tensile strength. Bags made from high-grade PP material should have a tensile strength above 25 MPa to ensure they can withstand the rigors of transportation and storage without tearing or rupturing.

Another critical feature is the bag's resistance to moisture and chemicals. Industry standards indicate that top manufacturers produce PP bags with excellent moisture-barrier properties, making them ideal for agricultural products, pharmaceuticals, and food packaging. Additionally, UV resistance is a notable aspect for those looking to use PP bags in outdoor settings, as prolonged sun exposure can deteriorate lower-quality bags within weeks. Many leading manufacturers provide bags with UV stabilizers, extending their lifespan and maintaining the integrity of the contents.

Choosing bags with these features not only enhances product safety but also ensures compliance with industry regulations, boosting brand reputation in today's competitive market.

The global PP bag market has witnessed significant growth, driven by a variety of materials and innovative packing solutions. Leading manufacturers are utilizing an array of plastics, including polypropylene (PP), polyethylene (PE), and polyethylene terephthalate (PET), to create bags and pouches that cater to diverse consumer needs. These manufacturers emphasize the quality and durability of their products, ensuring they can withstand the rigors of transportation and storage while maintaining sustainability initiatives.

In the comparative analysis of the top manufacturers within the PP bag industry, it becomes evident that each player has carved out a niche based on specific product types and market segments. For instance, some focus on producing heavy-duty trash bags made from low and high-density polyethylene (LDPE and HDPE), while others specialize in lighter, flexible solutions that appeal to eco-conscious consumers.

As these companies innovate and adapt to market trends, the competitive landscape will continue to evolve, leading to advancements in product design and materials used, ultimately enhancing consumer experience.

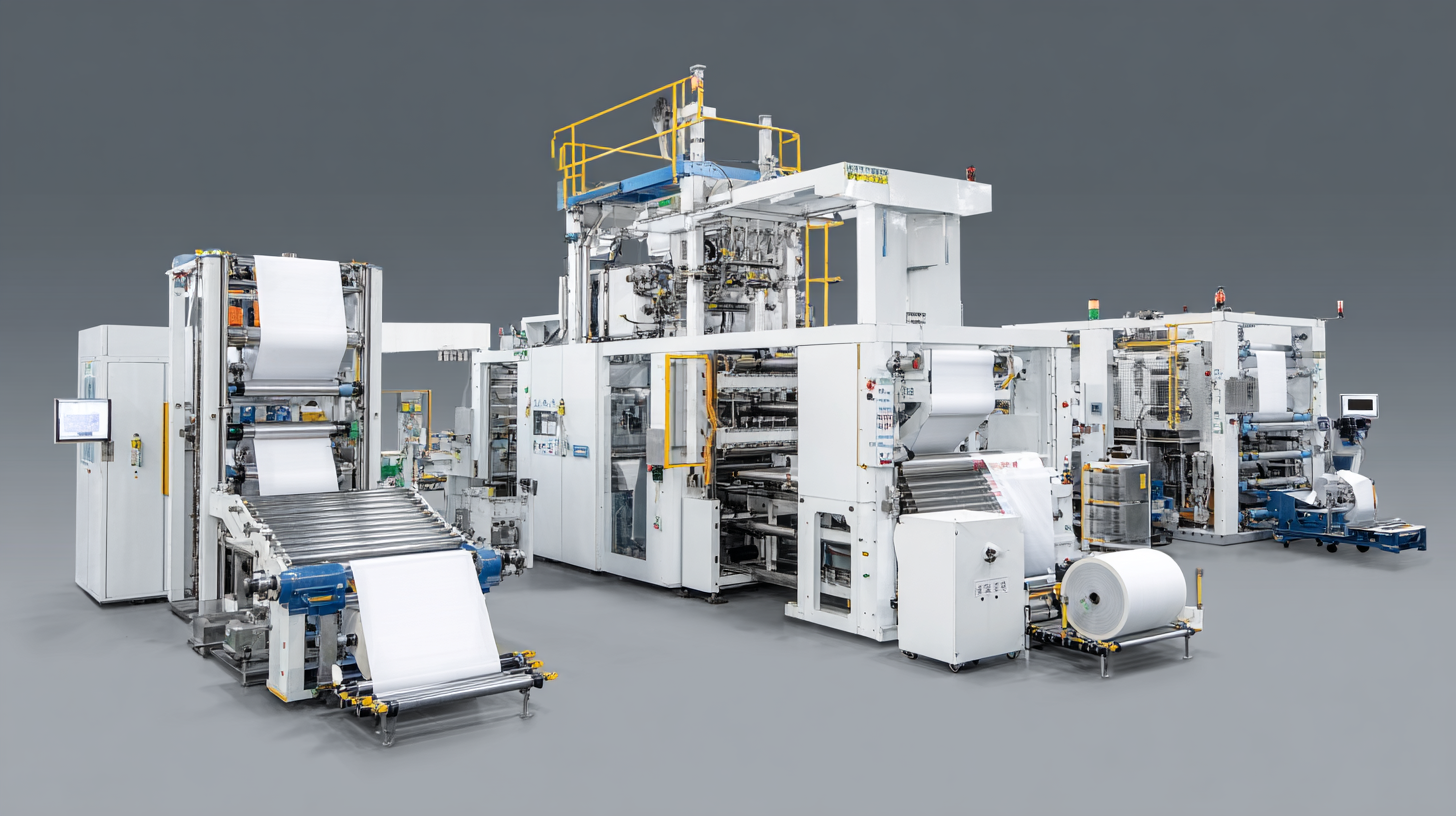

The landscape of polypropylene (PP) bag production is rapidly evolving, driven by innovative technologies that are reshaping how these essential packing solutions are manufactured. Advanced machinery and automation have streamlined production processes, increasing efficiency while reducing waste. State-of-the-art extrusion technologies now allow manufacturers to produce bags with tailored thicknesses and strengths, meeting diverse customer needs across various industries.

Moreover, the integration of smart technology in production lines provides real-time data analytics, enabling manufacturers to monitor performance and adjust processes instantaneously. This not only ensures consistent quality but also enhances flexibility in operations. The adoption of eco-friendly practices, such as using recycled materials and minimizing energy consumption, is becoming standard as sustainability takes center stage. As we look to the future, these innovations will play a crucial role in maintaining competitiveness in the global market for PP bags, ensuring that manufacturers can deliver high-quality, sustainable packing solutions that meet the demands of an increasingly conscious consumer base.

Sustainability in packaging is becoming increasingly vital as industries aim to reduce their environmental footprints. Among various packaging solutions, polypropylene (PP) bags are gaining traction for their recyclability and longevity. Recent reports indicate that the global sustainable packaging market is projected to reach approximately $500 billion by 2027, driven by rising consumer demand for eco-friendly alternatives. PP bags, in particular, are lighter and more energy-efficient to produce compared to traditional materials, minimizing their carbon impact.

Innovative approaches in the food packaging sector also reflect the growing focus on sustainability. For instance, the introduction of gelatin-based packaging and eco-friendly pouches have been shown to extend the shelf life of products such as poultry meat significantly. Studies reveal that gelatin pouches can reduce weight loss during storage, indicating their effectiveness in preservation while maintaining environmental integrity. This aligns with the broader movement where consumers increasingly favor brands that demonstrate commitment to sustainable practices, influencing packaging choices across various sectors including snacks, beverages, and more. The transition towards sustainable materials, including PP bags, not only supports environmental goals but also promotes brand loyalty among conscientious consumers.

The chart below illustrates the increasing trend of recycled content in PP bags from 2018 to 2022, demonstrating the shift toward sustainability in packaging solutions.